-

Flame Retardant

- Halogen Flame Retardant

- Phosphorus Flame Retardant

- Nitrogen Flame Retardant

- Silicon Flame Retardant

- Aluminum-Magnesium Flame Retardant

- Antimony Flame Retardant

- Boron Flame Retardant

- Expandable Graphite

- MOF Flame Retardant

- Nano Flame Retardant

- Hyperbranched Polymer Flame Retardant

-

Functional Flame Retardant

- Composite Flame Retardant for PA

- Composite Flame Retardant for PP

- Composite Flame Retardant for PBT

- Composite Flame Retardant for PVC

- Composite Flame Retardant for PU

- Composite Flame Retardant for Silicone Rubber

- Composite Flame Retardant for Epoxy Resin

- Composite Flame Retardant for TPU

- Composite Flame Retardant for TPE

- Cotton Durable Flame Retardant

- Polyester Durable Flame Retardant

- Semi-durable Flame Retardant

- Non-durable Flame Retardant

- Others

- Smoke Suppressant

- Flame Retardant Polymer

- Flame Retardant Masterbatch

Poly(dimethylsiloxane)

Inquiry| Catalog | ACM107517-8 |

| CAS | 107-51-7 |

| Structure | ![{[CurrentData.Name]}](https://resource.alfa-chemistry.com/structure/107-51-7.gif) |

| Description | Poly(dimethylsiloxane) (PDMS), also known as dimethicone, is an organosilicon compound that is widely used as a siloxane based elastomer. It is a hydrophobic material with attractive physical and chemical properties such as elasticity, optical transparency, tunable surface chemistry, and low electrical conductivity. |

| Synonyms | Octamethyltrisiloxane |

| IUPAC Name | dimethyl-bis(trimethylsilyloxy)silane |

| Molecular Weight | 236.53 |

| Molecular Formula | [(CH3)3SiO]2Si(CH3)2 |

| Canonical SMILES | C[Si](C)(C)O[Si](C)(C)O[Si](C)(C)C |

| InChI | 1S/C8H24O2Si3/c1-11(2,3)9-13(7,8)10-12(4,5)6/h1-8H3 |

| InChI Key | CXQXSVUQTKDNFP-UHFFFAOYSA-N |

| Boiling Point | 153 °C (lit.) |

| Melting Point | -82 °C (lit.) |

| Density | 0.82 g/mL at 25 °C (lit.) |

| Solubility | 1.44e-07 M;Immiscible with water;Immiscible with alcohol;Miscible with chloroform; soluble in chlorinated hydrocarbons, benzene, toluene, xylene, n-hexane, petroleum spirits, ether, amyl acetate; very slightly soluble in isopropyl alcohol; insoluble in methanol, acetone |

| Application | Poly(dimethylsiloxane) serves as a versatile compound with a wide range of applications due to its unique chemical properties. It is most commonly used as an antifoaming agent in various industrial processes and consumer products. In the food industry, it effectively prevents foaming and spattering in heated oils and minimizes foam formation during the production of wine, refined sugar, gelatin, and chewing gum. Its role in medical applications is also significant, being used extensively in prostheses like breast implants because of its low toxicity profile, as demonstrated by animal testing. Additionally, when combined with silica gel to form simethicone, it alleviates bloating by reducing gas bubble surface tension in the digestive system, making it a common ingredient in antacids and treatments for infant colic. Overall, poly(dimethylsiloxane) exemplifies the valuable characteristics of silicones, providing practical solutions across various sectors. |

| Packaging | 50 mL in glass bottle |

| RefractiveIndex | n20/D 1.384 (lit.) |

| Stability | Stable to heat and ... resistant to most chemical substances, although they are affected by strong acids. |

| Vapor Pressure | 3.34 mmHg |

| Viscosity | 1.0 cSt(25 °C) |

If the product of interest is not available in our catalog, please contact us to see if there is any relevant stock or other purchase channels.

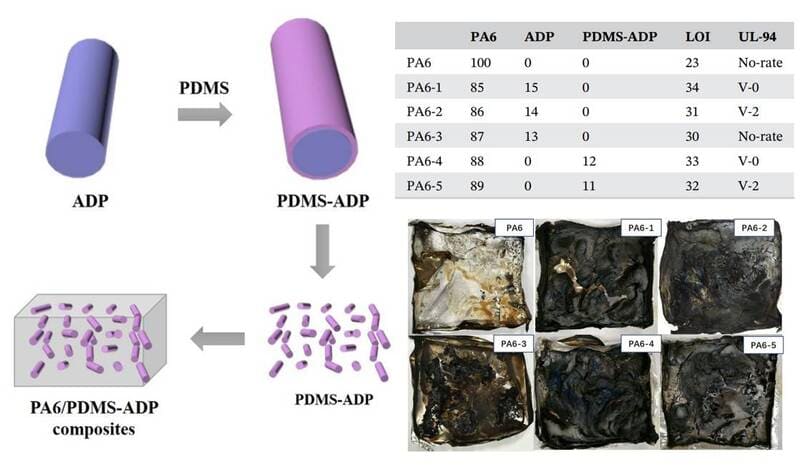

Cao, Cheng-Fei, et al. Chemical Engineering Journal, 2020, 393, 124724.

Cao, Cheng-Fei, et al. Chemical Engineering Journal, 2020, 393, 124724.

Pan, Ying, et al. Journal of Applied Polymer Science, 2020, 137(35), 49027.

Pan, Ying, et al. Journal of Applied Polymer Science, 2020, 137(35), 49027.